How Drones and Cloud Computing Increase the Accuracy of Silage Inventory

More and more dairies are using drone technology to measure the size of their forage piles and more accurately estimate the amount of feed they have in inventory for the next year. The technology is enabling dairies to get within just a few days of predicting when they may run out of feed. That could be particularly helpful to others this year in drought-stricken areas where forage tonnage has been lighter than usual. A drone and cloud-computed data calculations for forage pile measurement is replacing previous estimation methods. That includes measurement wheels, surveying equipment, hand calculations or just broad percentage reductions from the total forage tonnage harvested.

How it works

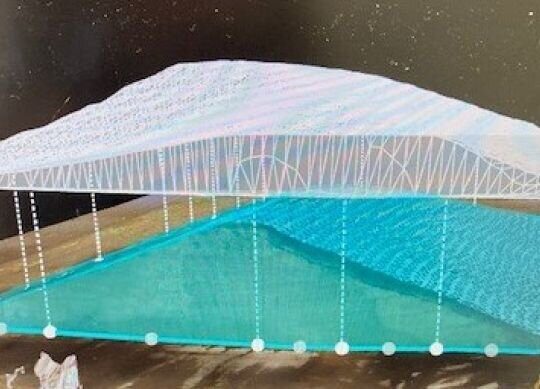

A drone equipped with a high-definition-resolution (HDR) camera is flown over a silage pile. The drone takes images of the pile – its height, contours and any side walls – and saves them to a memory card on the drone. When the drone lands, the images are uploaded to a commercial cloud-computing service that translates the images into a digital representation of the pile’s shape. This essentially provides the cubic volume of that captured image’s shape. But that’s not the end.

Forages can be packed at various densities (measured in pounds per cubic feet). To estimate how much feed could be stored in that cubic volume, an estimated density must be added to the equation. Due to safety concerns related to large silage piles, they aren’t testing forage pack densities. Rather, the inventory is estimated based on a range of different pack densities (from 14, 16, 18, etc. pounds per cubic foot). Usually the farm has an idea of what their pack densities have been in the past. Applying the estimated pack density, one can use the estimated cubic foot produced by the drone and the cloud-computing software to do some simple math calculations and arrive at an estimated as-fed tons held in storage.

Technology to measure forage piles is a carryover from technology used to measure large piles of construction material such as sand, rock and gravel. What a drone sees and captures is essentially the same for a pile of gravel as a pile of silage. The biggest difference in calculating cubic feet of the two substances is density. When it comes to inorganic materials, density is mostly fixed. With organic substances, like silage or haulage, density changes based on packing pressure.

One of the advantages of having more accurate forage inventory numbers is that it now helps to make the decision in the fall about exactly how many acres of corn to chop and put up as silage versus plan to sell as dry corn. Often, farms put everything up as silage to make sure they would be long on feed. But with more accurate inventories, the dairy can feel more confident converting some of their crop to a commodity that can wait for an optimal time to market and then convert it into cash flow.

Managing forage inventories is also of interest to bankers. Some banks are requiring feed be listed as an asset on the balance sheet. Having accurate feed inventory numbers is pleasing lenders. It’s also helpful to nutritionists.

Measuring forage inventories using drone technology is easier for nutritionists than going over a pile with a measuring wheel. Nutritionists can estimate fairly accurately, but firm numbers can be better. Drones technology can be much more accurate. It’s also more accurate than just guessing inventory based on weighing inventory as it goes in for packing and then guessing on a shrink percentage. On most farms, it is suggested that piles are flown twice a year – in the fall to give an inventory estimate and months later after the pile may have settled and shrunk a bit to update the accuracy of the inventory.

Drone flown and cloud-computed silage inventories have been well received in Wisconsin and Minnesota and the I-29 corridor. There’s also growing interest in California, Texas and New Mexico. The efficiency and accuracy of drone technology is more recognized and sought after, especially as drones and computer programs because more cost effective.

Nobis Agri Science has a drone and the software capabilities to estimate forage inventory. Contact your Nobis Agri Science nutritionist with any questions you have about utilizing drone technology.

Adapted from Walt Cooley for Progressive Dairy.